Inventory Stratification

Inventory stratification is the systematic classification of inventory to optimize management efforts. Based on the Pareto Principle, or the 80/20 rule, ABC analysis is a core method for this classification, asserting that a small percentage of items account for a large percentage of value. This blog post provides a glossary of key terms for understanding and implementing effective inventory stratification.

The ABCs of Inventory Stratification

Pareto Principle (80/20 Rule): This principle states that roughly 80% of a company’s sales or inventory value comes from 20% of its items. In inventory management, this means that focusing control efforts on the most valuable items will yield the greatest impact.

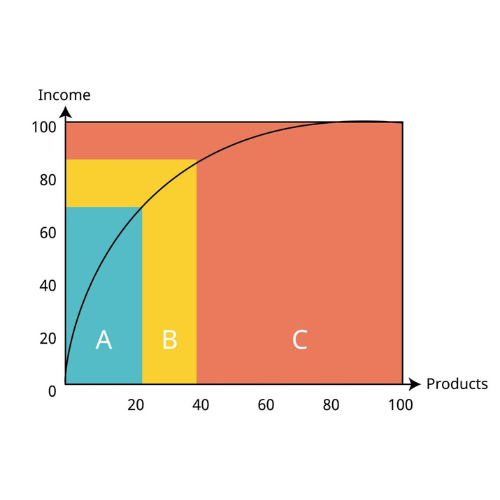

ABC Analysis: This method classifies inventory into three categories based on consumption value, which is the annual demand multiplied by the unit cost.

ABC analysis graph is an inventory categorization technique. ABC analysis divides an inventory into three categories of level of stock need to be controlled or monitor closely

A Items (Red): These are the high-value, fast-moving items that constitute approximately 10-20% of the total inventory items but account for 70-80% of the total consumption value. They require strict control, frequent cycle counts, and accurate demand forecasting.

B Items (Green): These are the intermediate-value items, making up about 30% of the total inventory items and 15-20% of the total consumption value. They receive moderate control and are reviewed regularly.

C Items (Blue): These are the low-value items that make up the majority of the inventory (around 50-60%) but only contribute 5-10% to the total consumption value. They require less stringent control, often managed with simple reorder points.

Additional Key Inventory Management Terms

Cycle Counting: A regular, ongoing process of counting a small subset of inventory to verify accuracy. It is a more efficient alternative to a full physical inventory count. Cycle counting is often prioritized for A items to maintain high levels of data accuracy.

Safety Stock: The extra quantity of an item held in inventory to mitigate the risk of stockouts caused by variations in demand or lead time. Calculating an appropriate safety stock level is critical for ensuring service levels are met without incurring excessive carrying costs.

Slob Inventory: An acronym for Slow-Locations, Obsolescence, Broken. This term refers to inventory that is difficult to locate, has become obsolete, or is damaged and unsaleable. Effectively managing Slob inventory is crucial for freeing up warehouse space and improving inventory accuracy.

Seasonality: The predictable, recurring pattern of demand fluctuations that occurs at specific times of the year. Understanding seasonality is key to accurate forecasting and preventing both stockouts during peak seasons and excess inventory during off-seasons.

Coefficient of Variation (CV): A statistical measure of the dispersion of demand data around the mean. It is calculated as the standard deviation of demand divided by the average demand. A high CV indicates high demand variability, which necessitates a larger safety stock to prevent stockouts.

Economic Order Quantity (EOQ): The ideal order quantity a company should purchase to minimize total inventory costs, including ordering costs and holding costs. EOQ helps determine the most economical batch size for replenishing stock.

Lead Time: The time between placing an order for an item and receiving it. Reducing lead time is a key strategy for lowering required inventory levels and improving responsiveness to demand changes.

By understanding these terms, managers and engineers can develop a robust framework for classifying and managing their inventory, leading to improved operational efficiency and reduced costs.